Incremental forming

The main advantage of incremental forming is that it is well suited for low cost prototyping or small batches of manufactured products. It can be used to create complex shapes with very simple tools. Because it is done with CAD/CAM the tool path can be created quickly and the changes are easy to apply. It can be done on any CNC milling machine or industrial robot, which also contributes to its cost-effectiveness.

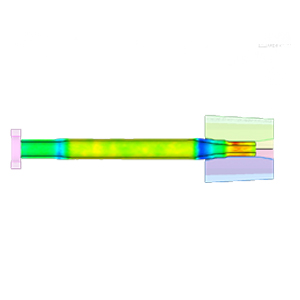

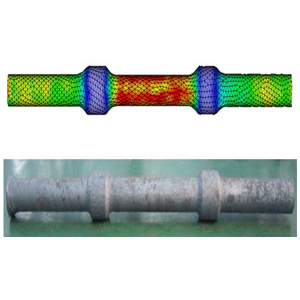

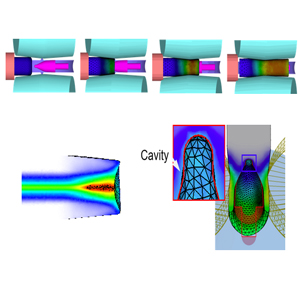

Analysis of multi-stage hollow shaft swaging process Analysis of multi-stage hollow shaft swaging process |

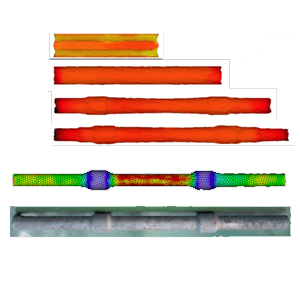

Elastoplastic finite element analysis Elastoplastic finite element analysis |

Socketing simulation Socketing simulation |

Chipless forming (flow forming)

Elongation process |

Diametric expansion process |

Hollow cylinder with diametric and axial elongation

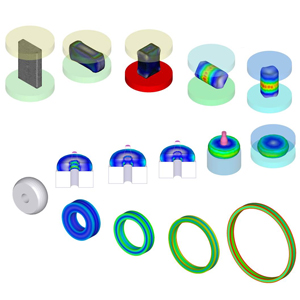

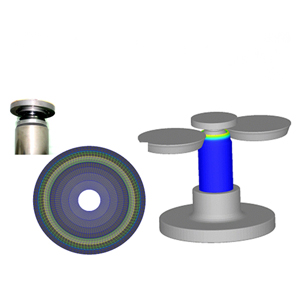

Large bearing manufacturing Large bearing manufacturing |

Radial ring forging Radial ring forging |

Radial forging of stepped or prismatic bar Radial forging of stepped or prismatic bar |

Open-die forging

Profiled round rod Profiled round rod |

Spacial warm radial forging process Spacial warm radial forging process |

Simple round rod Simple round rod |

Radial forging

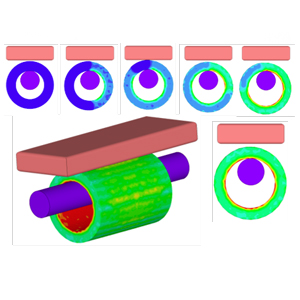

Roll forging |

|

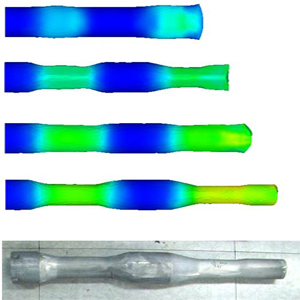

Roll forging

Mannesmann effect |

Roll piercing |

Roll piercing

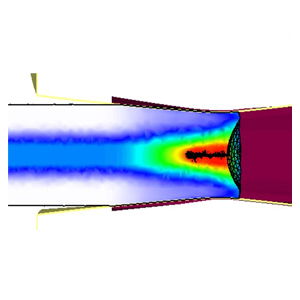

Socketing simulation |

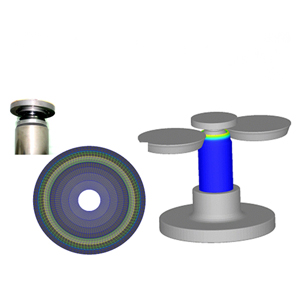

Rotary forging simulation |

Rotary forging

Swaging |

Rotary forging simulation |

Swaging

Contact Us

SEND YOUR SUPPORT SERVICE REQUESTS ON BUSINESS TIMES AND DAYS, MONDAY TO FRIDAY

| PT Arisma Data Setia

| PT Arisma Data Setia