Conventional forging

With conventional forging, as the dies approach, the alloy plastically deforms and flows laterally touching the side walls of the die. The alloy continues to flow outside of the impression forming flash. a the flash thins it cools causing resistance to additional deformation. The cooled flash then adds pressure to the inside of the die cavity to promote metal flow into any design impressions that are unfilled.

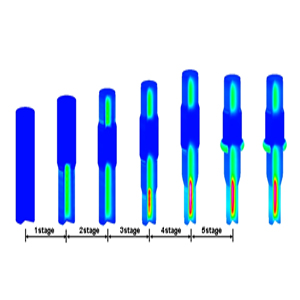

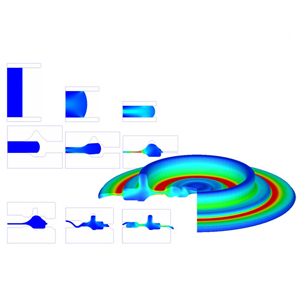

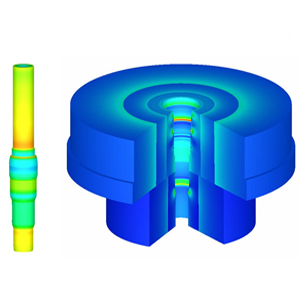

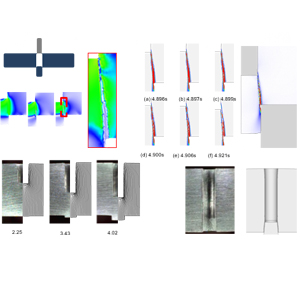

Simulation of a precision shaft cold forging process Simulation of a precision shaft cold forging process |

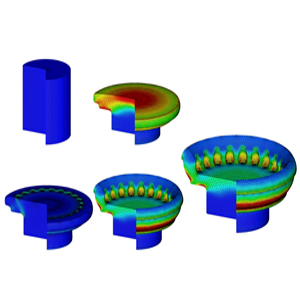

Simulation of an agricultural machinery part forging Simulation of an agricultural machinery part forging |

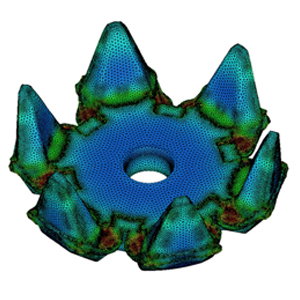

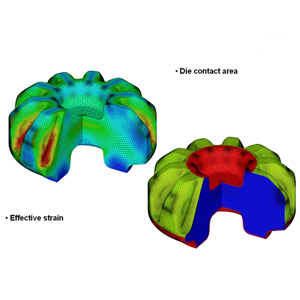

Simulation of rotor pole forging simulation Simulation of rotor pole forging simulation |

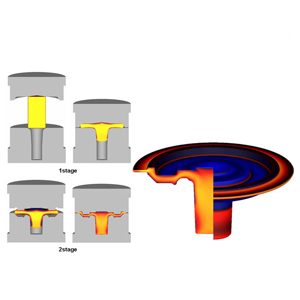

Automatic multi stage forging

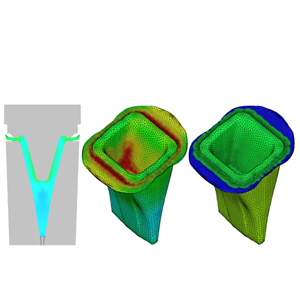

Simulation of ripper tooth hot forging process Simulation of ripper tooth hot forging process |

Simulation of a hub hot forging process Simulation of a hub hot forging process |

Simulation of a self-contacting problem Simulation of a self-contacting problem |

Closed die forging with flash

3D simulation of an axi-symmetric forging process 3D simulation of an axi-symmetric forging process |

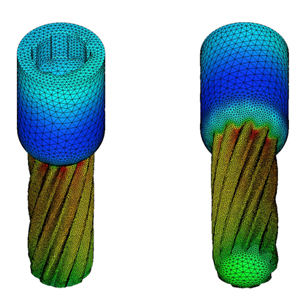

Simulation of a helical gear forging process Simulation of a helical gear forging process |

Simulation of a steering pinion forging process Simulation of a steering pinion forging process |

Closed die forging without flash

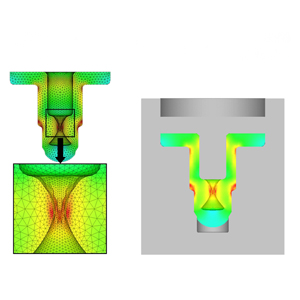

Die elastic deformation in cold forging Die elastic deformation in cold forging |

The failure case of ballstud cold forging process The failure case of ballstud cold forging process |

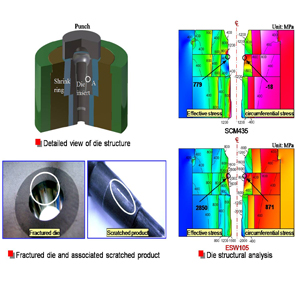

Die structural analysis of the precision shaft forging Die structural analysis of the precision shaft forging |

Die structural analysis

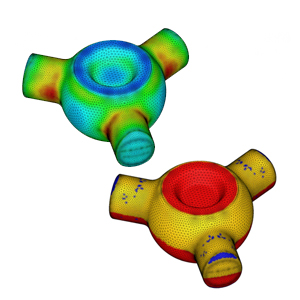

Tripod forging simulation Tripod forging simulation |

Long shaft bevel gear forging simulation Long shaft bevel gear forging simulation |

Intelligent forging simulation Intelligent forging simulation |

Enclosed die forging

Micro-forming |

Micro forming or large scale workpiece forming

Piercing 2D and 3D |

Deep piercing |

Piercing

Contact Us

SEND YOUR SUPPORT SERVICE REQUESTS ON BUSINESS TIMES AND DAYS, MONDAY TO FRIDAY

| PT Arisma Data Setia

| PT Arisma Data Setia