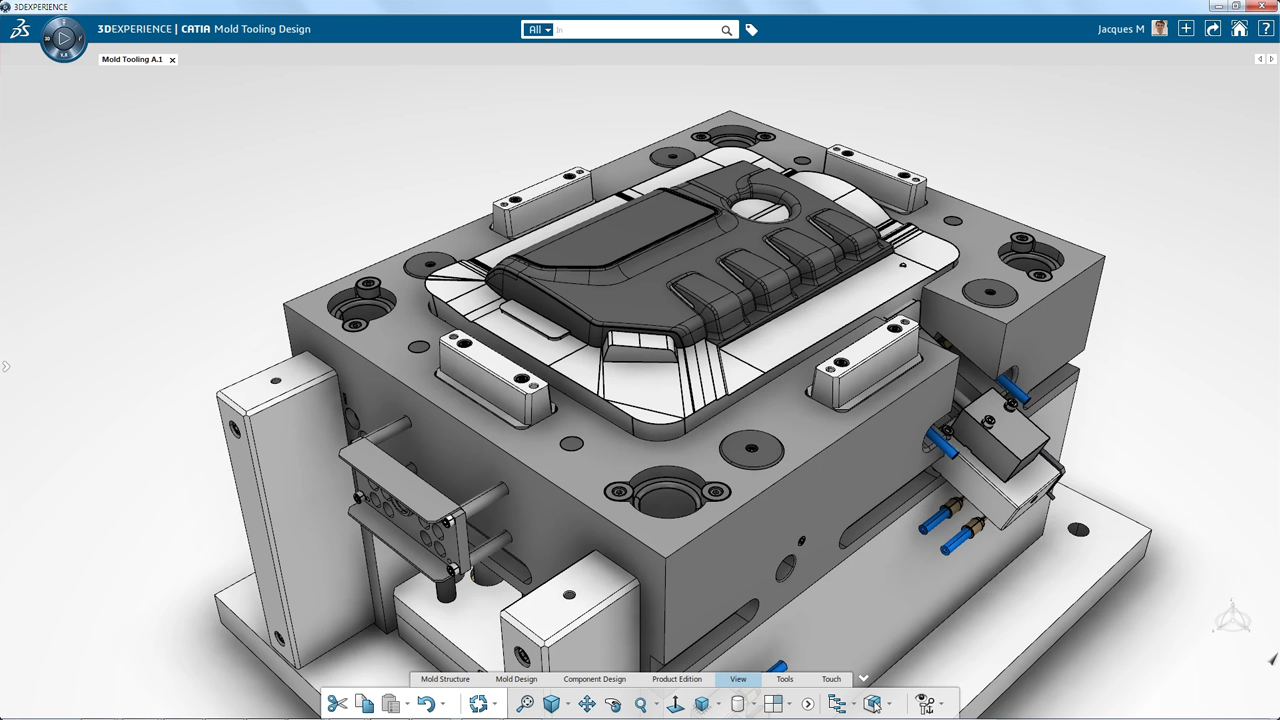

CATIA MOLD & TOOLING DESIGNER

The CATIA Mold and Tooling Designer role enables a flexible and highly customizable approach from conceptual to detailed mold tooling design. This role enables the user to automate design tasks and assist user decision-making at any step of a complex mold design:

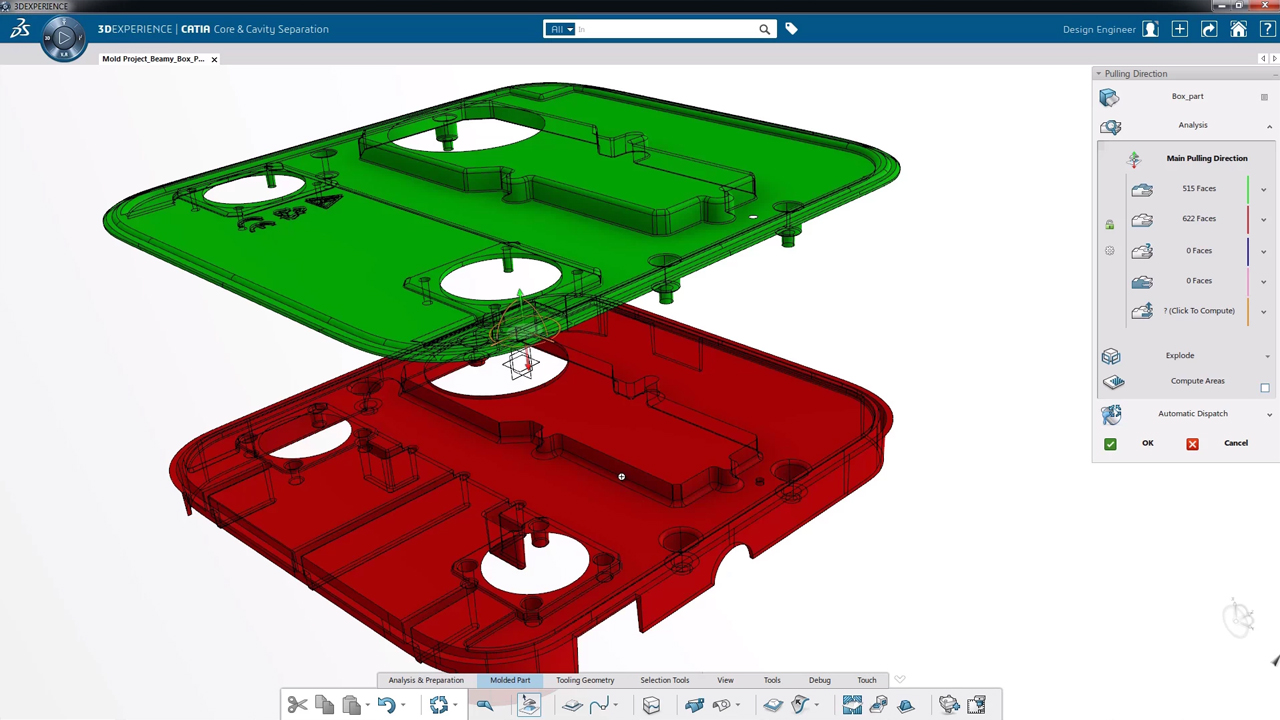

Conceptual design for bidding process including accurate pulling direction and wall thickness analysis, placeholder for ejectors and cooling systems

Conceptual design for bidding process including accurate pulling direction and wall thickness analysis, placeholder for ejectors and cooling systems

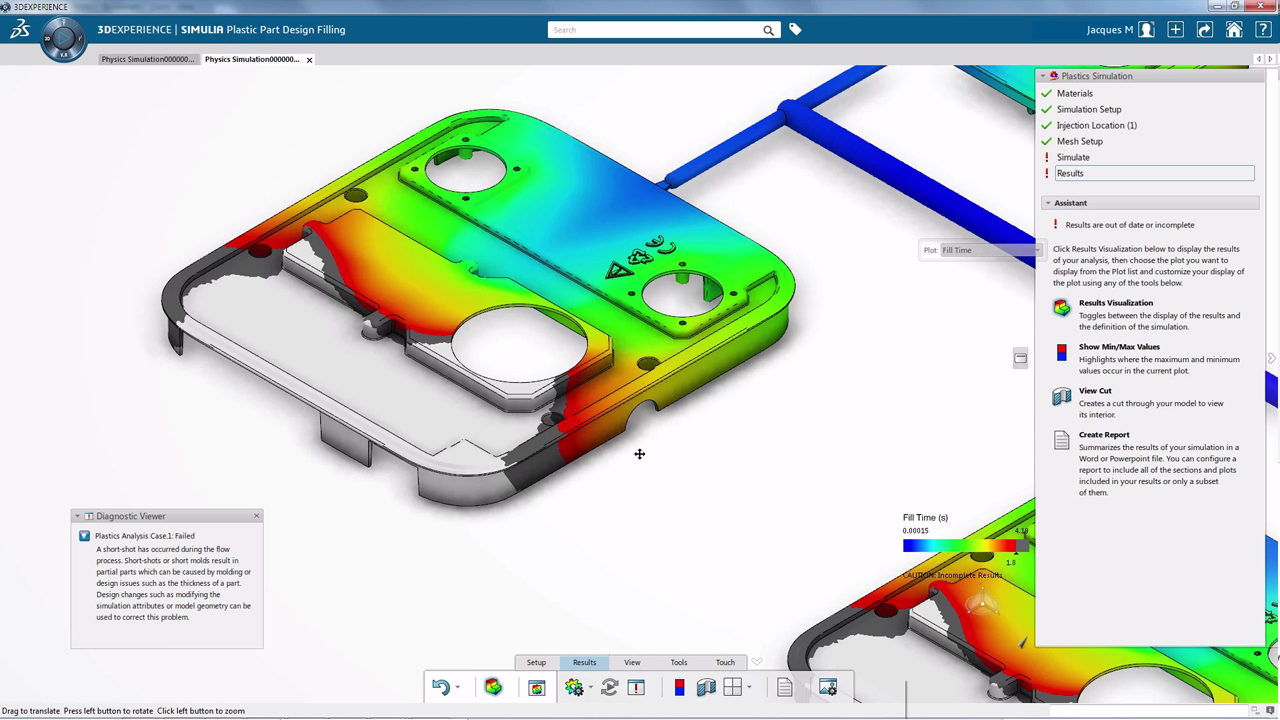

Anticipate and check manufacturing compliance with plastic injection simulation integrated in the environment of the mold designer

Anticipate and check manufacturing compliance with plastic injection simulation integrated in the environment of the mold designer

Extract parting lines and parting surfaces in dedicated features providing a unique design change automation

Extract parting lines and parting surfaces in dedicated features providing a unique design change automation

Catia Re-use complex mechanical systems for earlier kinematics validation

Catia Re-use complex mechanical systems for earlier kinematics validation

Re-use company know-how captured in smart components

Re-use company know-how captured in smart components

Catalogs of standard Moldbases equipped with smart components from most of the mold tooling suppliers

Catalogs of standard Moldbases equipped with smart components from most of the mold tooling suppliers

Seamless 3D Electrode design

Seamless 3D Electrode design

HUBUNGI KAMI SEKARANG

Harga & Support Terbaik Sejak 1996

0813-5000-4156 (JAKARTA OFFICE)

031-8074179 (SIDOARJO OFFICE)